PLG系列上排风多级流化床喷雾造粒干燥机

一、PLG系列上排风多级流化床喷雾造粒干燥机--设备概述

承揽UHT奶、巴氏奶、酸奶、花色奶、乳酸饮料、各种奶粉、冰淇淋、炼乳、干酪、奶油、干酪素、奶啤等工程。

《各种粉料速溶造粒干燥工程》

承揽各种营养粉剂、咖啡伴侣、骨粉、血粉、肉粉、酪盐酸钠等工程。

《果蔬制品干燥工程》

承揽南瓜粉、苹果汁、莲子乳、莲芯茶、莲蓉饼干、柑桔酒、山楂粉、胡萝卜粉、甘草粉、花生粉、花生油等工程。

《豆制品干燥工程》

承揽豆粉、豆奶、豆酸奶、大豆分离蛋白等工程。

PLG series upper exhaust multi-stage fluidized bed spray granulating dryer

喷雾干燥机|上排风流化床喷雾干燥制粒机|卧式压力喷雾造粒干燥机

Spray dryer | Upper exhaust fluidized bed spray granulator | Horizontal pressure spray granulator dryer

江苏博鸿提供的喷雾干燥机,压力喷雾干燥塔,离心式喷雾干燥机,卧式压力喷雾干燥机,流化床喷雾干燥制粒机,上排风多级流化床喷雾造粒干燥机,中药浸膏喷雾干燥机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥设备性能稳定,模块化设计,为您提供先进的喷雾干燥整体解决方案和实验喷雾干燥工艺实验样机。江苏博鸿是高品质喷雾干燥设备生产厂家,已提供超数百套高品质喷雾干燥设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong spray dryer, pressure spray drying tower, centrifugal spray dryer, horizontal pressure spray dryer, fluidized bed spray granulating machine, upper exhaust multi-stage fluidized bed spray granulating dryer, Chinese medicine extract spray dryer, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying equipment stable performance, modular design, to provide you with advanced spray drying solutions and experimental spray drying process experimental prototype. Jiangsu bohong is a high quality spray drying equipment manufacturers, has provided more than hundreds of high quality spray drying equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

在喷雾干燥方面进行了大量的试验研究。使其在乳粉加工上,采用了多支喷枪喷雾,旋风捕粉技术,微粉由风送系统送至塔顶,实现微粉与雾滴之间的附聚。还采用了振动流化床二次干燥、冷却,卵磷脂喷涂等技术。经过附聚后的乳粉形成中空颗粒,热物理状态和速溶性。振动流化床二次干燥、冷却,可使乳粉在降速干燥过程中延长干燥时间,节约能源。干燥后的乳粉迅速冷却,即可包装,避免了二次污染,大大提高了乳粉的质量。

PLG series upper exhaust multi-stage fluidized bed spray granulating dryer -- equipment overview

A lot of experiments have been done in spray drying. In the processing of milk powder, a number of spray gun spray, cyclone powder technology, micro powder sent by the air system to the top of the tower, to achieve the cohesion between micro powder and fog drops. The technology of secondary drying and cooling of vibrating fluidized bed and coating of lecithin were also used. The condensed milk powder forms hollow particles, and the thermophysical state and instant solubility are improved obviously. The secondary drying and cooling of vibrating fluidized bed can prolong the drying time of milk powder in the process of decreasing drying speed and save energy. The dried milk powder can be quickly cooled and packaged to avoid secondary pollution and greatly improve the quality of milk powder.

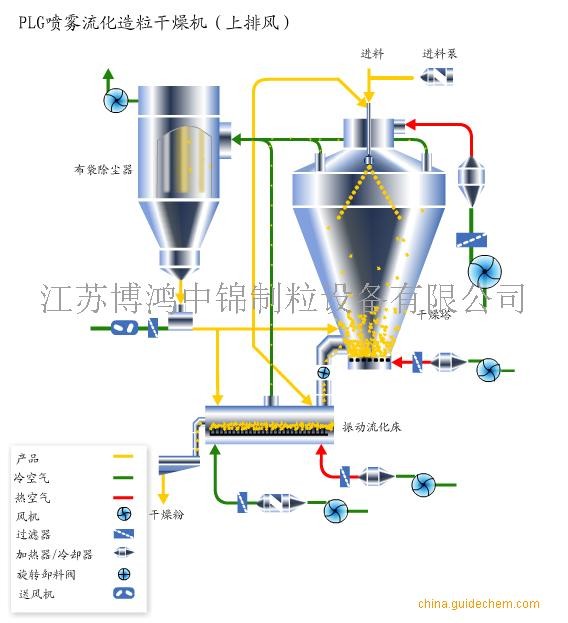

二、PLG系列上排风多级流化床喷雾造粒干燥机--设备原理

下排风干燥塔是顺流干燥,塔内不能形成环形风幕。粉的色泽和颗粒度都较差。而上排风塔是混流干燥,雾滴的流程是恒速干燥期为顺流,降速期为混流排风,风到达底部时形成180度大回转,使干燥中的乳粉和空气进行分离,分离后的空气顺塔壁向上急速运动直达排风口。风在急速向上运动中在塔壁和乳粉之间形成大的环形风幕,控制粉挂壁现象,而且,回转中的细粉与喷雾的雾滴重新造粒,使粉的色泽和颗粒度都较下排风塔好。

PLG series upper exhaust multi-stage fluidized bed spray granulator dryer - equipment principle

The lower exhaust air drying tower is downstream drying, the tower can not form a circular wind curtain. The color and granularity of powder are poor. While the upper exhaust tower is mixed flow drying, the flow of fog drops is constant speed drying period for downstream flow, the descending period for mixed flow exhaust, the wind reaches the bottom to form a 180 degree giant turn, so that the dry milk powder and air to separate, the separated air along the wall of the tower to the outlet rapidly. In the rapid upward movement of the wind, a large circular air curtain is formed between the tower wall and the milk powder to control the phenomenon of the powder hanging on the wall. In addition, the fine powder and spray droplets in the rotation are re-granulated, so that the color and granularity of the powder are better than that of the lower exhaust tower.

三、PGL系列上排风多级流化床喷雾造粒干燥机--设备特点

1、喷雾塔内的热风由塔顶至排风口经过180°改变方向通过四点对成的排风管排出,保证塔内热风不跑偏,利用重力沉降原理使较大粉粒落至塔锥部.排风入口风速较低,进入风管后风速较高,解决了风管内存粉现象,减轻旋风分离器和风送系统的负担。

2、喷雾塔壁、旋风分离器均装有新式气锤,振击力量可调,每个气锤振击力量、间隔时间,由脉冲控制仪自动控制,解决了塔壁挂粉, 奶粉受热时间长和出粉不均的问题,提高了产品质量,为振动流化床正常工作创造了有利条件。

3、旋风分离器排出的微粉经过振动输粉机均匀进入吹粉器由罗茨鼓风机由微粉送至塔顶两支喷枪之间或振动流化床,实现颗粒之间附聚,颗粒与雾滴之间附聚提高产品的速溶性。

4、塔顶冷却系统冷却塔顶进风口,喷枪及微粉输送管,确保塔顶和微粉输送管无焦粉,喷枪不堵塞,避免回塔细粉过热引起蛋白变性。

5、采用多喷头,是塔与流化床排除的微粉回收送至多喷头间,实现雾滴附聚和微粉与雾滴附聚,使产品颗粒为具有毛细管的附聚结构,且无微粉,提高冲调性。

6、加热器采用抽屉式装配,使更换、维修、更加方便。

7、合理布置清扫门,使扫塔方便、安全。

8、两段振动流化床采用可调整频率的震动电机震动,结构简单,故障少,维修方便。粉粒流化层均匀,流化效果好.进行包装,避免产品的二次污染。流化床整体焊接,内部无死角,易清洗,减少污染。

9、具有各种仪表、工艺流程图的电气控制箱,可供操作人员随时掌握喷雾干燥系统工作情况。根据用户要求可以配置参数自控系统和防爆装置。为节约能源和提高加热器片的使用寿命,用冷凝水对进风预热。

10、根据用户的需要可提供配置有塔内固定床的上进风和上排风干燥塔、可自动出粉的卧式干燥箱、布袋扑粉干燥塔和生产特殊产品的(番茄粉、初乳粉、香焦粉、血粉、鸡肉粉等)低温干燥塔。

PGL series upper exhaust multistage fluidized bed spray granulator dryer -- equipment features

1, hot air spray tower outlet from the top to change direction by four o 'clock after 180 ° of the exhaust duct discharge into, ensure the hot air in the tower is not running deviation, using the gravity settling principle drop large powder grain to cone. Exhaust inlet wind speed is low, into the duct wind speed is higher, after solved the phenomenon of duct memory powder, reduce the burden of cyclone separator and the wind to send system.

2, spray tower wall, cyclone separator with new pneumatic hammer, adjustable vibration strike force, each pneumatic hammer vibration strike force, time interval, controlled by the pulse instrument automatic control, solve the tower wall hanging powder, milk powder, the problem of uneven heating time is long and the powder, improved product quality, have created favorable conditions for the normal work of the vibrating fluidized bed.

3. The micro powder discharged from the cyclone separator enters the powder blower evenly through the vibrating powder conveyor. Roots blower sends the micro powder to the top of the tower between the two spray guns or the vibrating fluidized bed.

4. Cooling system at the top of the tower cools the air inlet at the top of the tower, the spray gun and the micro powder conveying pipe to ensure that there is no coke powder on the top of the tower and micro powder conveying pipe, and the spray gun is not blocked, so as to avoid the protein denaturation caused by overheat of the fine powder back to the tower.

5. Multiple nozzles are used to recycle the micro powder from the tower and fluidized bed and send it to the nozzles to realize the atomization of fog drops and the atomization of micro powder and fog drops, so that the product particles are of capillary structure with no micro powder and improve the toning property.

6, the heater adopts drawer-type assembly, so that the replacement, maintenance, more convenient.

7. Reasonably arrange the cleaning door to make the tower convenient and safe.

8. The two-stage vibrating fluidized bed is vibrated by adjustable frequency vibration motor, with simple structure, few faults and convenient maintenance. The powder fluidized layer is even and the fluidized effect is good. Fluidized bed integral welding, internal no dead Angle, easy to clean, reduce pollution.

9, with a variety of instruments, process flow chart of the electrical control box, for the operation of the spray drying system at any time. The automatic control system and explosion protection device can be configured according to the user's requirements. In order to save energy and improve the service life of the heater, condensate water is used to preheat the inlet air.

10. According to the needs of users, it can provide a drying tower equipped with a fixed bed inside the tower, a horizontal drying box that can automatically produce powder, a drying tower for cloth bag powder and a low-temperature drying tower for special products (tomato powder, colostrum powder, coke powder, blood powder, chicken powder, etc.).

《喷雾干燥机适用产品范围》

Scope of applicable products of spray dryer

《氨基酸及有机酸类产品干燥工程》

《Drying engineering of amino acid and organic acid products》

1、承揽氨基酸类产品:谷氨酸、赖氨酸、蛋氨酸、色氨酸、苏氨酸、苯丙氨酸、甘氨酸、丙氨酸、胱氨酸、半胱氨酸、丝氨酸、酪氨酸、脯氨酸、精氨酸、组氨酸、鸟氨酸、瓜氨酸、茶氨酸、支链氨基酸等。

1. Amino acid products: glutamic acid, lysine, methionine, tryptophan, threonine, phenylalanine, glycine, alanine, cystine, cysteine, serine, tyrosine, proline, arginine, histidine, ornithine, citrulline, theanine, branched amino acid, etc.

2、承揽有机酸类产品:柠檬酸、葡萄糖酸、乳酸、衣康酸、酒石酸、苹果酸、琥珀酸、丙酮酸、长链二元酸、脂肪酸等。

2. Organic acid products: citric acid, gluconic acid, lactic acid, itaconic acid, tartaric acid, malic acid, succinic acid, pyruvate, long-chain dibasic acid, fatty acid, etc.

《淀粉及淀粉糖类产品干燥工程》

1、承揽淀粉糖及玉米淀粉、薯类淀粉、玉米蛋白粉、玉米油、蛋白饲料、各种DE值葡萄糖浆、麦芽糖、麦芽糊精、果葡糖浆、各种用途的变性淀粉、高吸水淀粉、粘结剂等。

《Drying engineering of starch and starch sugar products》

1, contract starch sugar and corn starch, potato starch, corn protein powder, corn oil, protein feed, various DE value glucose syrup, maltose, maltodextrin, fructose syrup, various USES of modified starch, high water absorption starch, binder, etc.

2、多元醇类产品:山梨醇、木糖醇、麦芽糖醇、甘蔗。

2. Polyol products: sorbitol, xylitol, maltitol, sugarcane.

3、露醇、乳糖醇、异麦芽酮糖醇、阿拉伯糖醇、赤藓。

3. Dew alcohol, lactose alcohol, iso-maltoketol, arabinol, erythritum.

4、醇、丙二醇、1-3丙二醇、乙二醇、丁二醇、氢化5)淀粉糖浆、糖醇及其衍生物。

4. Alcohol, propylene glycol, 1-3 propylene glycol, glycol, butanediol, hydrogenated 5) starch syrup, sugar alcohol and its derivatives.

《酶制剂类产品干燥工程》

承揽淀粉酶、糖化酶、蛋白酶、纤维素酶、异淀粉酶、异构酶、β—萄聚糖酶、植酸酶、果胶酶、脂肪酶、木聚糖酶等。

《Drying engineering of enzyme preparation products》

Amylase, glycosylase, protease, cellulase, isoamylase, isomerase, glucanase, pectinase, lipase, xylanase, etc.

《酵母及其衍生物类产品》

承揽高活性干酵母、药用酵母、饲料酵母、营养酵母、酵母抽提物等。

《Yeast and its derivatives products》

Contract high activity dry yeast, medicinal yeast, feed yeast, nutritional yeast, yeast extract, etc.

《功能发酵制品类产品干燥工程》

承揽香菇多糖、灵芝多糖、冬虫夏草、红曲色素、低聚异麦芽糖及各种功能糖醇等。

《Drying engineering of functional fermentation products》

Lentinan, ganoderma lucidum polysaccharide, cordyceps sinensis, red koji pigment, oligomeric isomaltose and various functional sugar alcohol, etc.

《屠宰场副产品》

承揽血和鱼制品类:动物蛋白、血(深色白蛋白、浅色白蛋白)、鱼蛋白、鱼粉、脑、鱼露、胶与水解胶、肝和鲸露。

《Slaughterhouse by-products》

Blood and fish products: animal protein, blood (dark albumin, light albumin), fish protein, fish meal, brain, fish sauce, glue and hydrolyzed glue, liver and whale sauce.

《乳制品干燥工程》

《Dairy drying project》

Contracted UHT milk, pasteurized milk, yogurt, color milk, lactic acid drinks, all kinds of milk powder, ice cream, condensed milk, cheese, cream, casein, milk beer and other projects.

《Instant granulation and drying project of various powder materials》

Contracted all kinds of nutritional powder, coffee companion, bone powder, blood powder, meat powder, sodium casehydrochloride and other projects.

《Drying engineering of fruit and vegetable products》

Contracted pumpkin powder, apple juice, lotus seed milk, lotus seed tea, lotus paste biscuits, citrus wine, hawthorn powder, carrot powder, licorice powder, peanut powder, peanut oil and other projects.

《Soybean drying project》

Contract soy flour, soy milk, soy yogurt, soy protein separation and other projects.