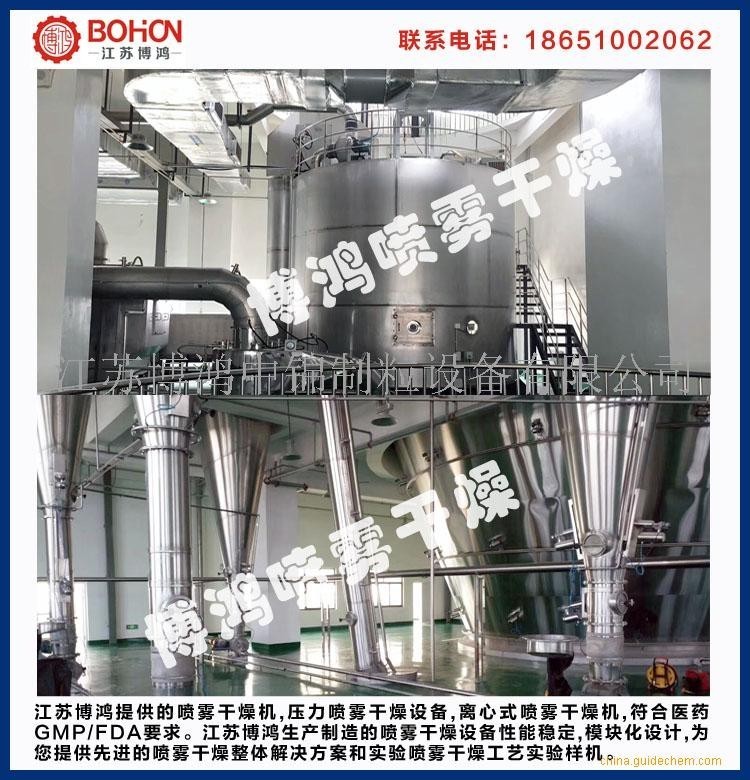

喷雾干燥机|流化床喷雾干燥制粒机|压力喷雾干燥机

江苏博鸿提供的喷雾干燥机,压力喷雾干燥设备,离心式喷雾干燥机,卧式压力喷雾干燥机,流化床喷雾干燥制粒机,上排风多级流化床喷雾干燥机,符合医药GMP/FDA要求。江苏博鸿生产制造的喷雾干燥设备性能稳定,模块化设计,为您提供先进的喷雾干燥整体解决方案和实验喷雾干燥工艺实验样机。江苏博鸿是高品质喷雾干燥设备生产厂家,已提供超数百套高品质喷雾干燥设备,客户遍布全国和欧洲/东南亚/中东等海外地区。

Jiangsu bohong spray dryer, pressure spray drying equipment, centrifugal spray dryer, horizontal pressure spray dryer, fluidized bed spray granulator, upper exhaust multi-stage fluidized bed spray dryer, in line with GMP/FDA requirements. Jiangsu bohong manufacturing spray drying equipment stable performance, modular design, to provide you with advanced spray drying solutions and experimental spray drying process experimental prototype. Jiangsu bohong is a high quality spray drying equipment manufacturers, has provided more than hundreds of high quality spray drying equipment, customers throughout the country and Europe/southeast Asia/the Middle East and other overseas regions.

一、牛奶分离蛋白喷雾干燥机--设备概述

牛奶分离蛋白喷雾干燥机是一种可以同时完成干燥和造粒的装置。按工艺要求可以调节料液泵的压力、流量、喷孔的大小,得到所需的按一定大小比例的球形颗粒。本机组工作过程为料液通过隔膜泵高压输入,喷出雾状液滴,然后同热空气并流下降,大部分粉粒由塔底排料口收集,废气及其微小粉末经旋风分离器分离,废气由抽风机排出,粉末由设在旋风分离器下端的授粉筒收集,风机出口还可装备二级除尘装置,回收率在96-98%以上。

PPG series pressure co-current spray dryer is a device can complete drying and granulation. According to process requirements, it can adjust the material pump pressure, flow, the size of the nozzle to get the required certain size ratio of spherical particles. The working process is high-pressure liquid feeding through the diaphragm pump, spray mist droplets, and then co-current with the hot air down, most of the powder are collected from the bottom of the discharge port, exhaust and tiny powder separated by cyclone, The exhaust gas is released from the exhaust blower, the powder is collected from the cyclone separator at the bottom, fan outlet port can also be equipped with secondary dust removal device, the recovery rate can reach 96-98%.

特点 Features

干燥速度快,料液经雾化后表面积大大增加,在热风气流中,瞬间就可蒸发95%-98%的水份,完成干燥的时间仅需要十几秒到数十秒种,特别适用于热敏性物料的干燥。

High drying speed, liquid surface is increased by the atomization, in the hot air flow, instantaneous evaporation of 95% -98% of the water, Only 10 seconds to tens of seconds to complete the drying, especially suitable for heat sensitive materials.

所有产品为球状颗粒,粒度均匀,流动性好,溶解性好,产品纯度高,质量好。

All products are spherical particles, uniform size, good fluidity, good solubility, high purity, good quality.

使用范围广,根据物料的特性,可以用热风干燥, 也可以用冷风造粒,对物料的适应性强。

Widely application, according to the characteristics of materials, it can be used in hot air drying, also cold granulation, High material adaptability.

操作简单稳定,控制方便,容易实现自动化作业。

Simple and stable operation, easy control and easily automatic operation.

适应物料 Application

化学工业:白炭黑、混凝土外加剂、硫酸钡、碱式硫酸铬、氧化铝、氧化钛、高岭土、铁氧体、块滑石、碳化物、肥料、染料、洗涤剂、ACR助剂、胶乳、净水剂、树脂、塑料、冰晶石等。

Chemical industry: white carbon black, concrete admixture, barium sulfate, basic chromium sulfate, alumina, titanium oxide, kaolin, ferrite, block talc, carbides, fertilizers, dyes, detergents, ACR additives, latex, Water purification agent, resin, plastic, cryolite and so on.

食品工业:糊精、麦芽糖、蛋白粉、蛋黄粉、低聚糖、颗粒油脂、速溶咖啡、淀粉、香料、果蔬颗。

Food industry: dextrin, maltose, protein powder, egg yolk powder, oligosaccharides, granular fat, instant coffee, starch, spices, fruit and vegetable stars.

乳品工业:脱脂奶粉、全脂奶粉、豆奶粉、冰淇淋粉、乳精粉、酷朊酸钠等。

Dairy industry: skimmed milk powder, whole milk powder, soy milk powder, ice cream powder, milk powder, cool acid sodium.

医药工业:中西药粉剂、抗 生素、生化产品、维生素、农药粉剂、水解蛋白、酶、单细胞蛋白等。

Pharmaceutical industry: Chinese and Western medicine powder, antibiotics, biochemical products, vitamins, pesticide powder, hydrolyzed protein, enzymes, single-cell protein.

建材工业:陶瓷坯料、釉料、超细粉料等

Building materials industry: ceramic blanks, glazes, ultra-fine powder and so on

环保:烟气脱硫、造纸黑液及药厂废液处理等。

Environmental protection: flue gas desulfurization, black liquor and pharmaceutical waste liquid treatment